AgilePlace for Manufacturing Teams

Historically, manufacturers have dealt with the headaches of process waste and bottlenecks daily, while still facing the challenge to deliver quality outcomes.

Planview AgilePlace™ enables manufacturing organizations to leverage Just in Time manufacturing and Kanban boards to better manage and visualize their processes.

By leveraging Kanban boards and analytics, manufacturers can:

- Improve the alignment of goals between business units.

- Highlight inefficiencies across siloed manufacturing plants.

- Create visibility into their work and productivity.

- Simplify the coordination of work across teams.

- Continuously improve their production processes over time.

Using Kanban In a Pull System

By moving from a traditional schedule-based approach to a pull system, teams can pull in production through their process as customers are asking for it, creating value.

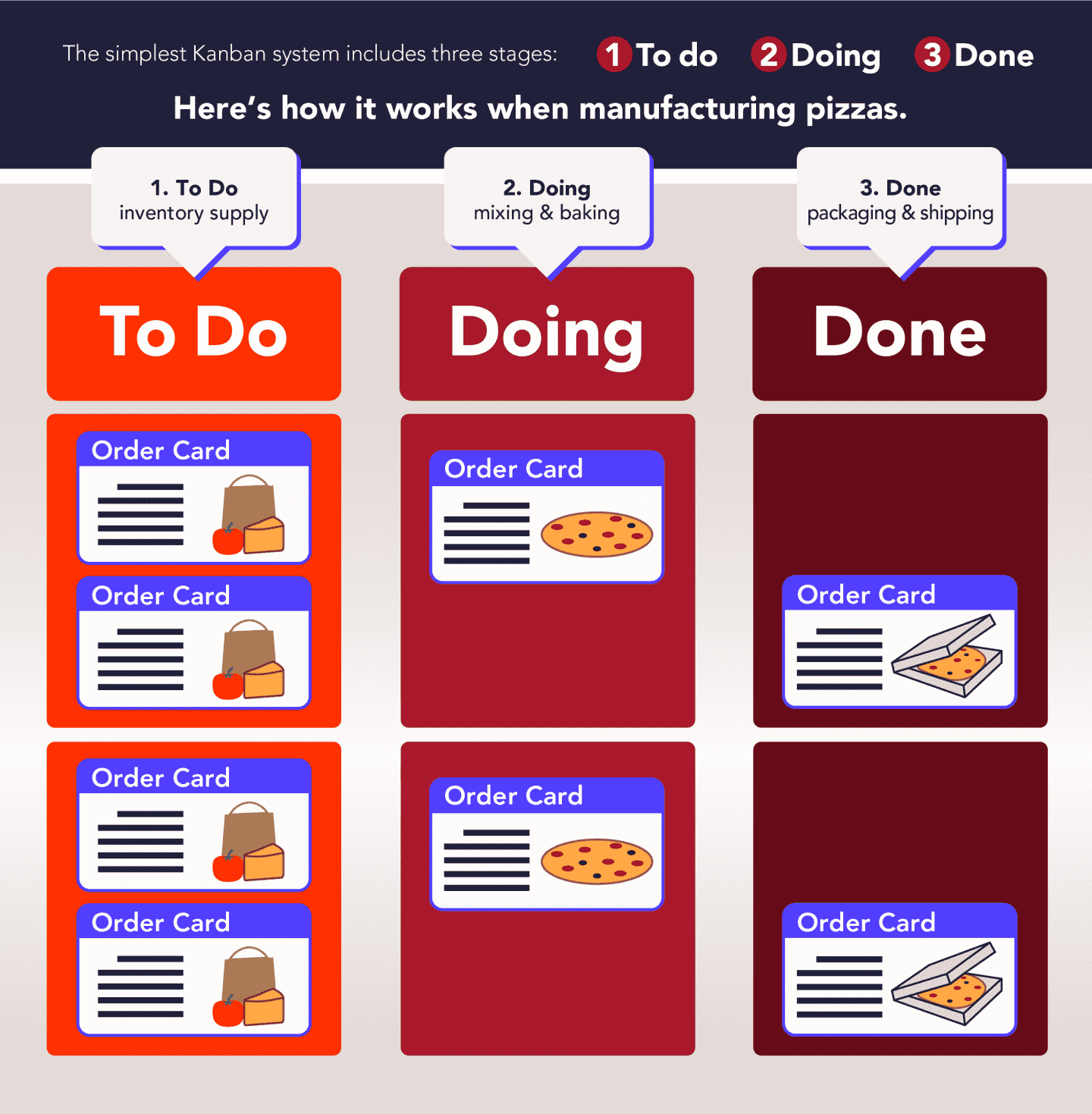

Below is an example of manufacturing pizzas:

- To Do: Inventory supply.

- Doing: Mixing and baking.

- Done: Packaging and shipping.

As boxes of pizza are shipped from the Done column, pull from the Doing column to the right, because more pizzas need to be baked based on the actual supply demand of customers.

Since more pizzas are being baked, more supplies are needed. Pull a To Do card to the right. By using Kanban, the company is only buying and baking what they need to fill orders avoiding excess inventory, and no stale pizzas.

Create a Board

AgilePlace provides many different options for boards that can be used to manage lean manufacturing processes. You can create your own board and fully customize it to match your process, or use one of our pre-built templates that closely aligns with your organization’s existing process.

TIP

You must be an Account Administrator or a Board Creator to see the New Board option. Only Account Administrators will see the Duplicate option.

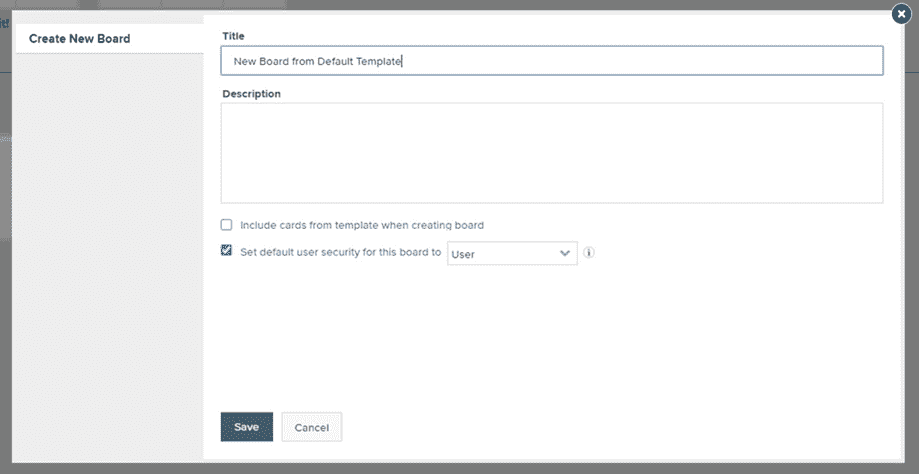

Default Template

1. Create a new board from the default template and add a Title and Description that reflects who will be using the board and for what purpose.

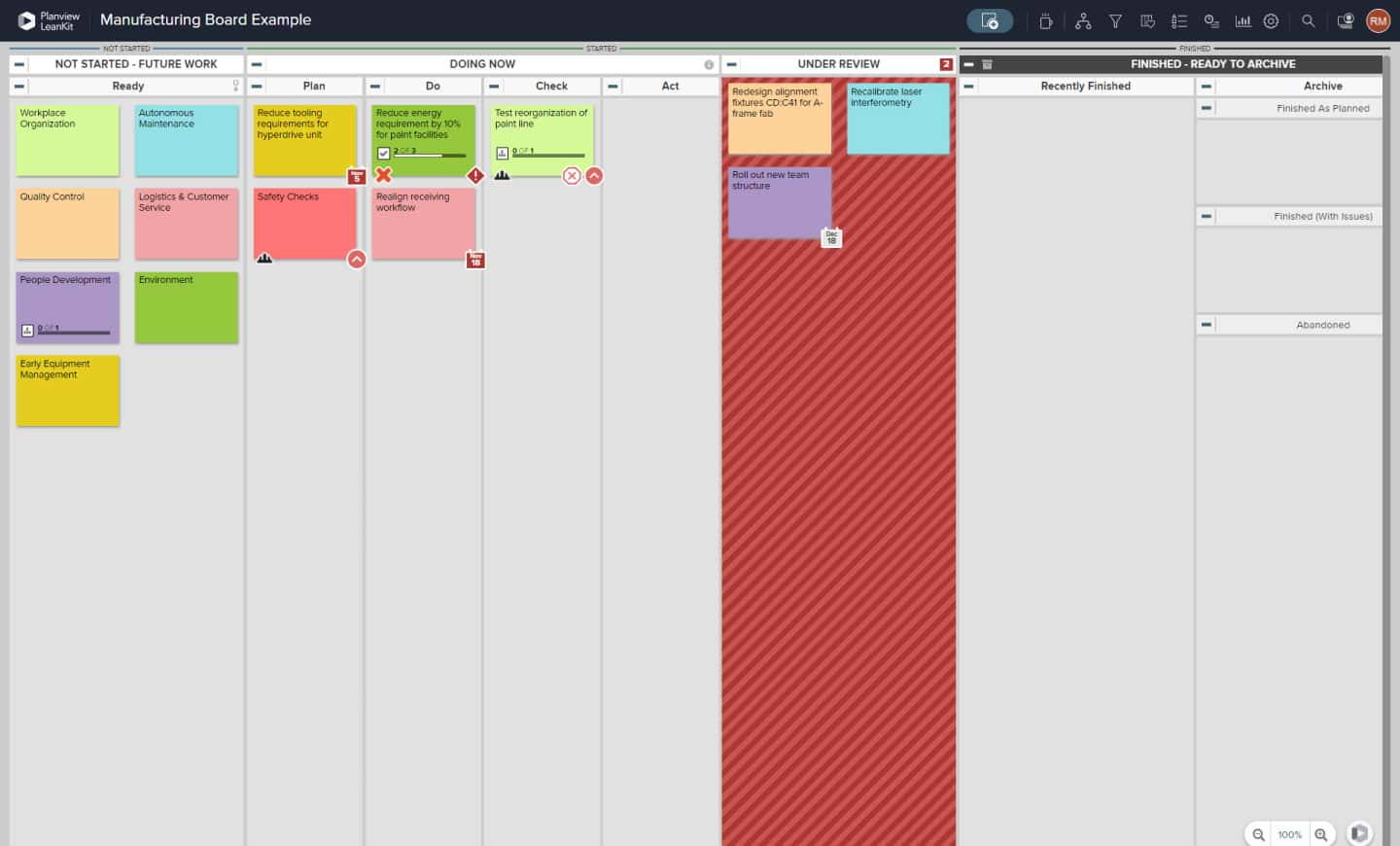

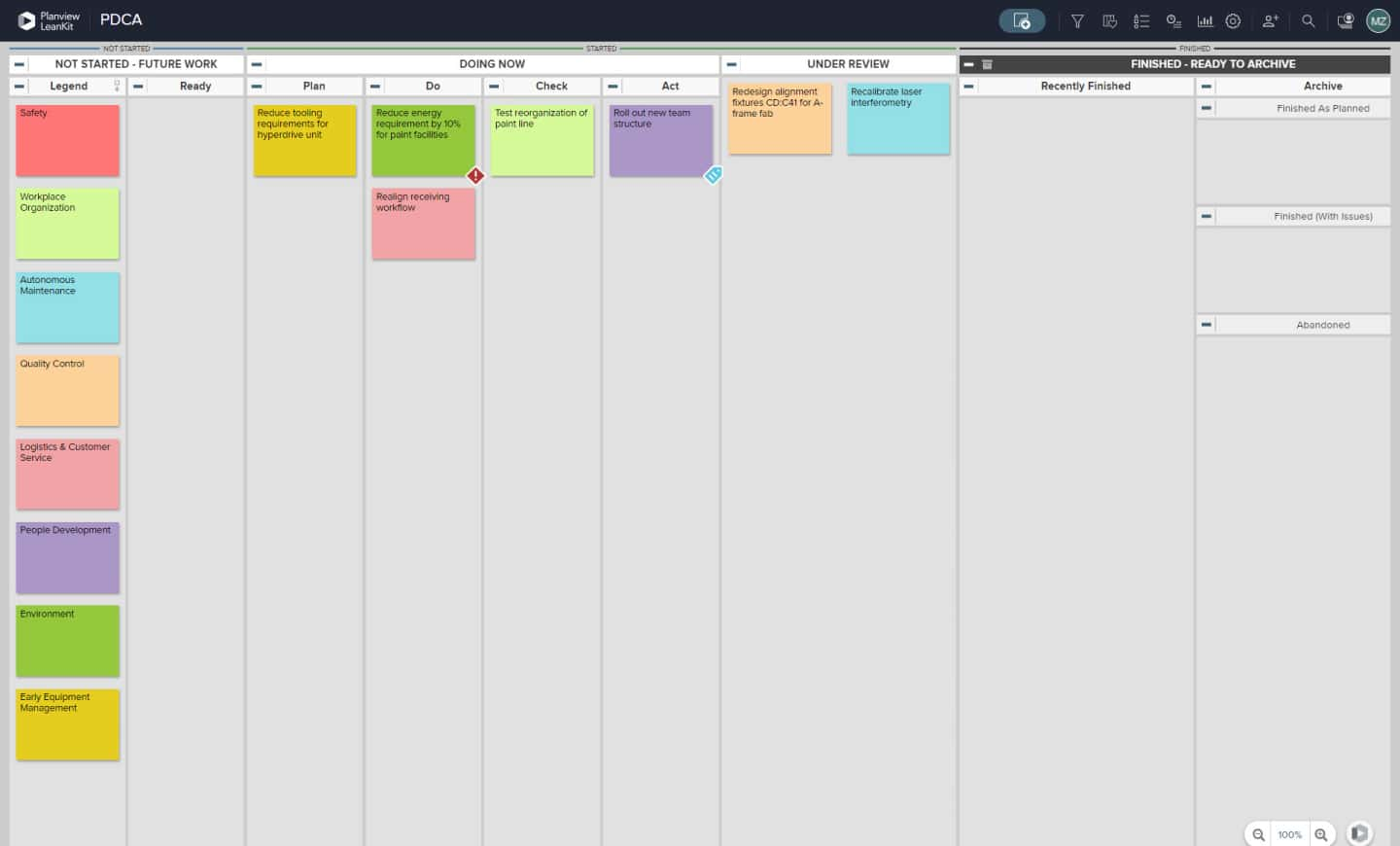

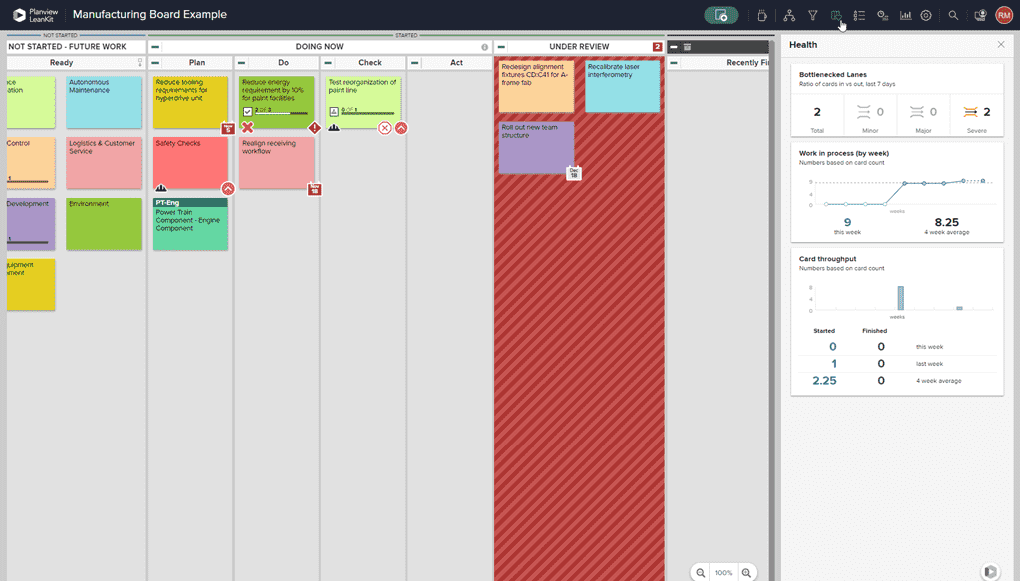

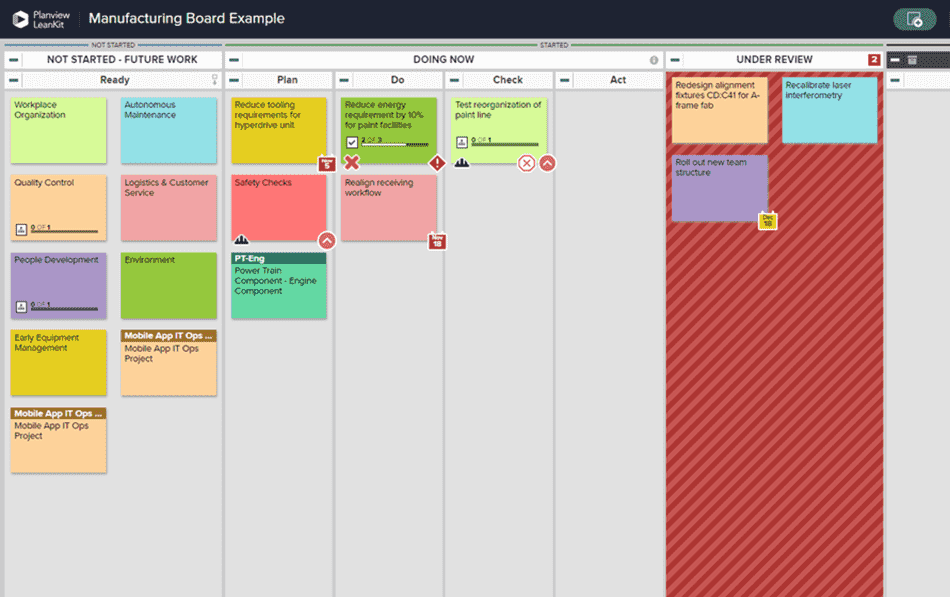

2. Optionally, edit your board layout to rename and/or divide the default not started, started, and finished lanes into steps that align with your process. Below is just one example of what your manufacturing board could look like:

ACTIVITY

Try this activity with your team to help identify the stages in your process:

- Have each team member write down the top three to five work items they have in process, using one sticky note per item. Be specific so that the whole team understands the details of each work item (for example, "designing new website layout” is better than “website”).

- Next, have each team member pick one sticky note from their collection and stick it to their shirt, to “become” that piece of work.

- Figure out where your piece of work is in your team’s process by asking the following three questions: Where am I right now? Where did I come from? Where will I go next?

Adapted from Kanban Roadmap: How to Get Started in 5 Easy Steps

Create a Board from the Template Library

PDCA Template

PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continuous improvement of processes and products. AgilePlace offers a PDCA board template under Engineering Operations & Manufacturing Boards.

If you choose to include cards with your template, the PDCA board appears as the template below:

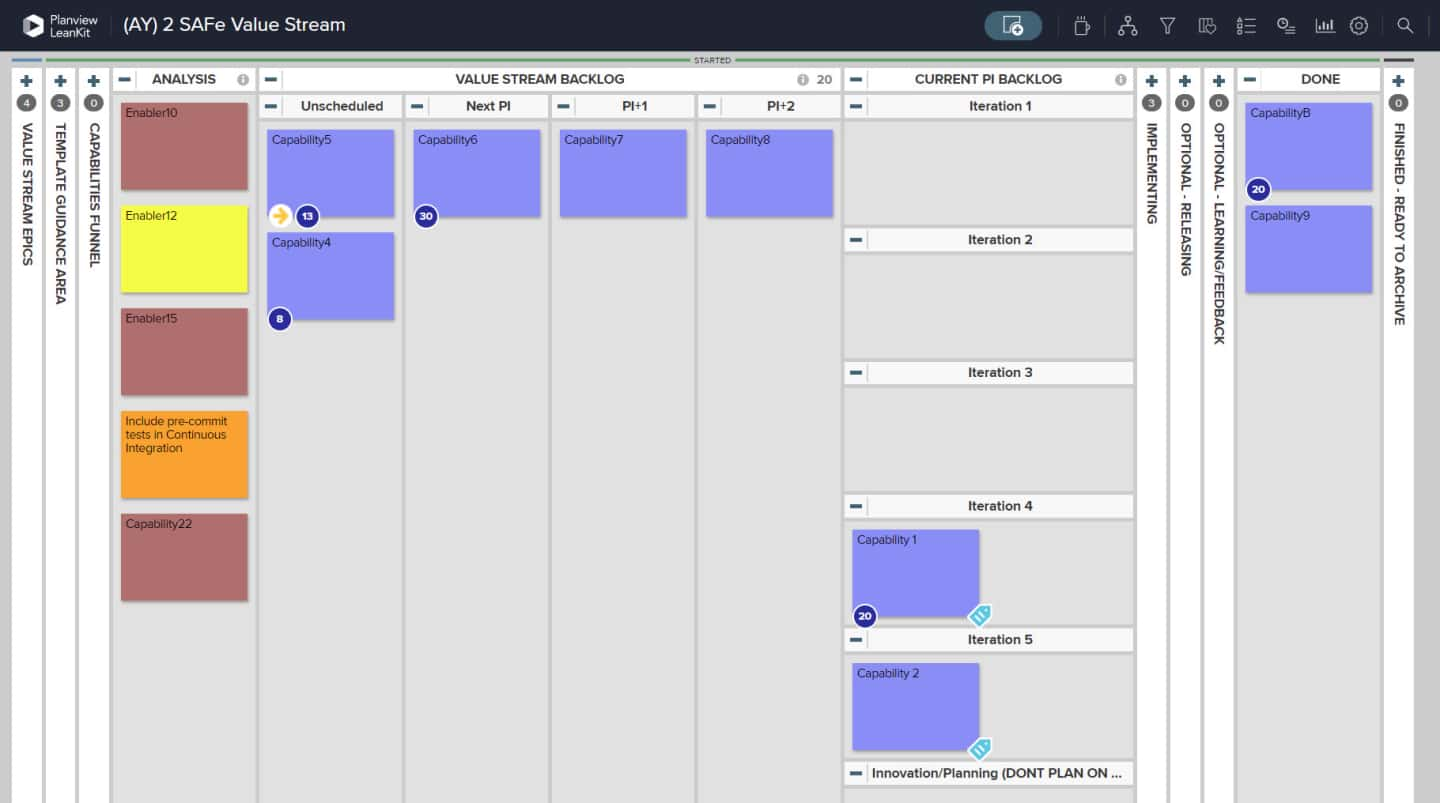

SAFe Templates

AgilePlace offers pre-built Kanban board templates for SAFe 4.0, making it easy for teams to jump in and get started immediately. These templates are based on the latest updates in SAFe and are intended to help practitioners at the portfolio, solution, program, and team levels implement Lean-Agile practices at enterprise scale.

For example, AgilePlace’s SAFe Value Stream board template helps manufacturing companies define and visualize the steps involved in getting a product, service, or value-adding project from ideation to the delivery of value to the end consumer. When performed effectively, value stream mapping can help organizations optimize the flow of value, creating a more efficient, predictable, and agile system.

Example of Manufacturing SAFe Value Stream Board

TIP

Interested in learning more about implementing SAFe in AgilePlace? Check out our Introduction to AgilePlace’s SAFe Templates.

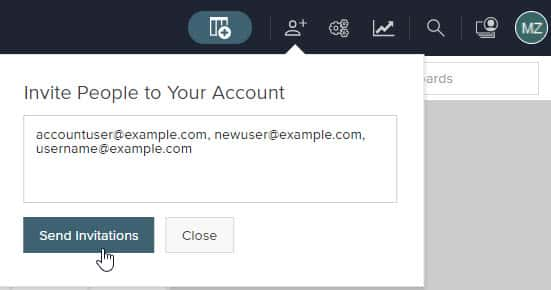

Invite Users

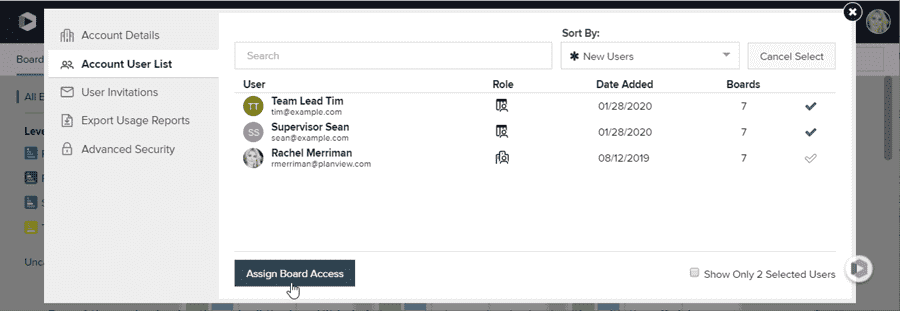

Next, invite users to the board so they can create cards and begin using the board. Every individual who interacts with your AgilePlace account will require their own unique user (login) account. User accounts are unique to individual people and cannot be shared.

1. Invite your team members to your organization's AgilePlace account. Each person will receive an email with an invitation to join AgilePlace and create their user account.

2. Set board user access to determine which actions users can take on the board. Depending on their user role, team members will be able to view the board, perform actions on cards, and edit the board's layout.

Create and Move Cards

Now that you’ve created your board and invited your team, it’s time to create cards and begin moving them through the board. In AgilePlace, cards usually represent pieces of work flowing through a process, with lanes representing the sequential steps in that process. Cards are moved to the appropriate lane on the board to represent the current status, making it easy for your team to quickly understand progress and priority of work items.

1. Create cards that represent your potential work items in your not started lanes, and your current work items in your started lanes.

TIP

Select Quick Create to quickly create a card and edit the details later or select a card type from the list that appears to create a card for a specific type of work item.

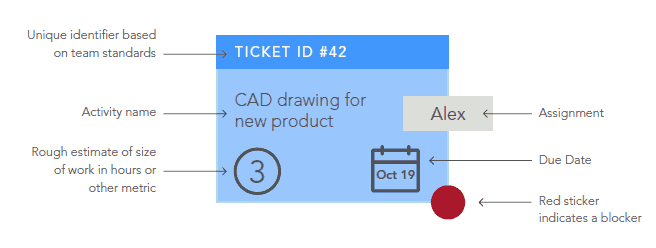

2. Edit your cards to add visual indicators and additional details about the work. Here's some of the basic information you'll want to include on a card:

- Header: Card headers are unique identifiers for your cards that can be used to track details from external systems, such as work order ID numbers.

- Assignee: Indicate who is in charge of a work item by assigning users to cards in any started lanes, and their avatar will appear on the face of the card.

- Planned Start and Finish Dates: You might choose not to have any dates on your cards, instead using lanes to represent sprints and other delivery cadences. But for certain types of time-sensitive work, setting planned start and planned finish dates on your card can help you visualize important deadlines. If your card is close to its planned finish date, the calendar icon will turn yellow. If it’s past the due date, it will turn red.

- Card Type: Using card types is one of the best practices of Kanban, because it’s an easy way to organize your work by project, type of work, or other process-based identifiers. For example, the Flint Hills manufacturing team uses card types on their board for: Mechanical, Maintenance, Electrical, Inspection, Installation, Outage/Shutdown, etc.

- Priority: Prioritizing cards enables teams to know which cards to pull from the backlog first. And since priority is based on overall strategy and value, you can be more confident when making trade-off decisions if you run into capacity issues.

- Size: Sizing can help teams capture estimated effort for each card, enabling them to plan their backlog of work and manage work in process. Approaches to card size (sometimes also referred to as points) vary by team. For example, you can use a scale that corresponds to t-shirt size (e.g., 1 equals extra small, 2 equals small, etc.), a scale of 1 through 10, or a detailed estimate for hours of effort.

- Custom Icons: Custom icons are a secondary option for visually categorizing work in addition to card types. For example, you can use them to identify which customer a card is for, which geographic region a card is connected to, or what product a card pertains to.

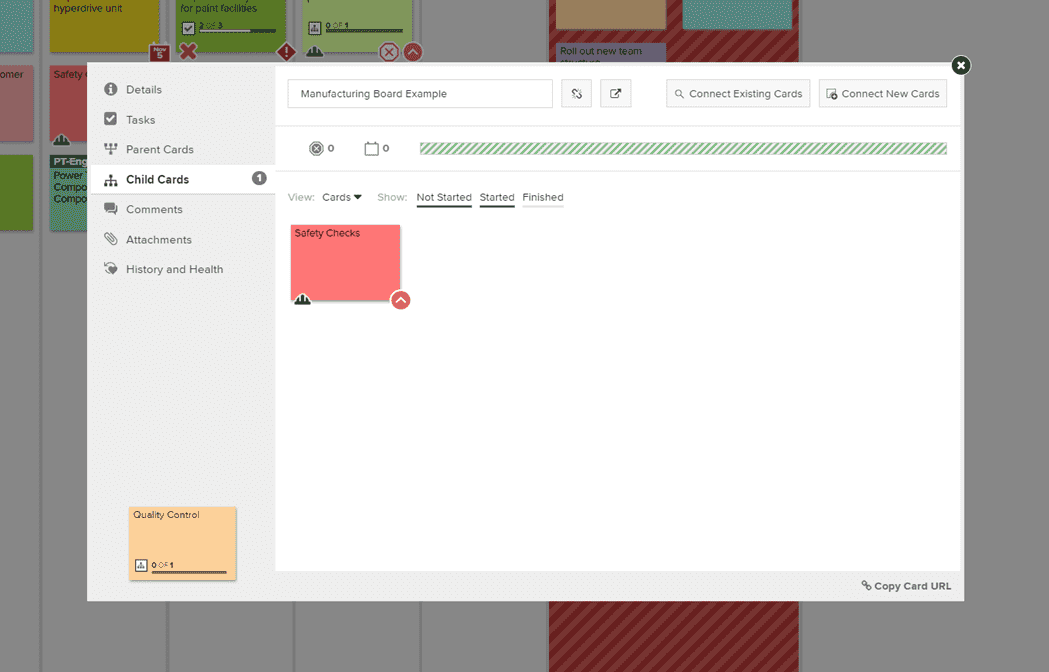

3. Create parent-child connections between cards to track and manage the progress of work distributed across multiple teams or to communicate rollup information to stakeholders.

Once you’ve established parent-child connections between cards, statistics at the parent card level help you quickly assess the progress of child cards and identify potential problems.

4. Move cards left to right on the board. As the piece of work which the card represents is pulled from one stage of the process to the next, the card is moved from lane-to-lane on the board.

ACTIVITY

Standup Meetings

For teams using Kanban boards to manage their work, daily stand-ups are a great way to reinforce the most helpful practices of Kanban, such as observing flow, resolving issues, and helping everyone stay engaged. Stand-ups also energize the team, keep work moving forward, and help teams predict and prevent potential roadblocks before they snowball into larger issues.

5. Block cards as needed to signal that an item is stuck and can’t move ahead to the next step in the process. In lean manufacturing, jidoka (or stop the line) is the practice of pausing a production line when an error occurs, in order to identify the cause of the error and correct it. Everyone on your team will be able to see the reason why a card is blocked, encouraging team members to work together to quickly come up with effective, permanent solutions to problems.

TIP

View a card's history and health to see how many times it has been blocked, where in the process the card was blocked, and how long the card stayed blocked.

Practice Continuous Improvement

The goal of continuous improvement is to help teams improve, continuously. By encouraging manufacturing teams to identify, prioritize, and intentionally complete work items one at a time, while providing an actionable way for teams to practice continuous improvement, Kanban can drastically improve productivity, efficiency, and morale.

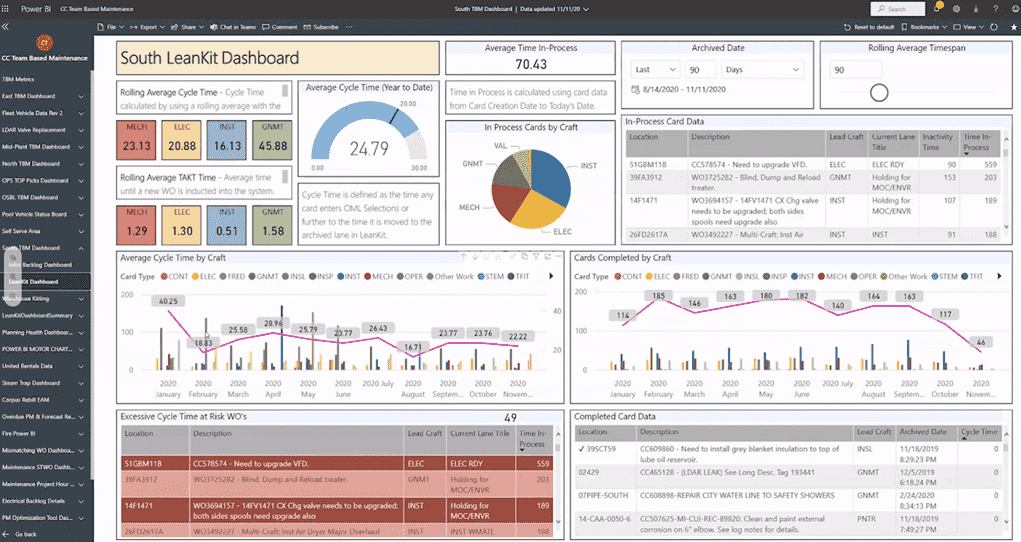

Track Metrics

Lean manufacturing metrics, such as lead time, cycle time, throughput, and cumulative flow help organizations measure the impact of their improvement efforts. Collecting, analyzing, visualizing, and socializing these metrics (through shared dashboards) is essential to promoting transparency and driving change.

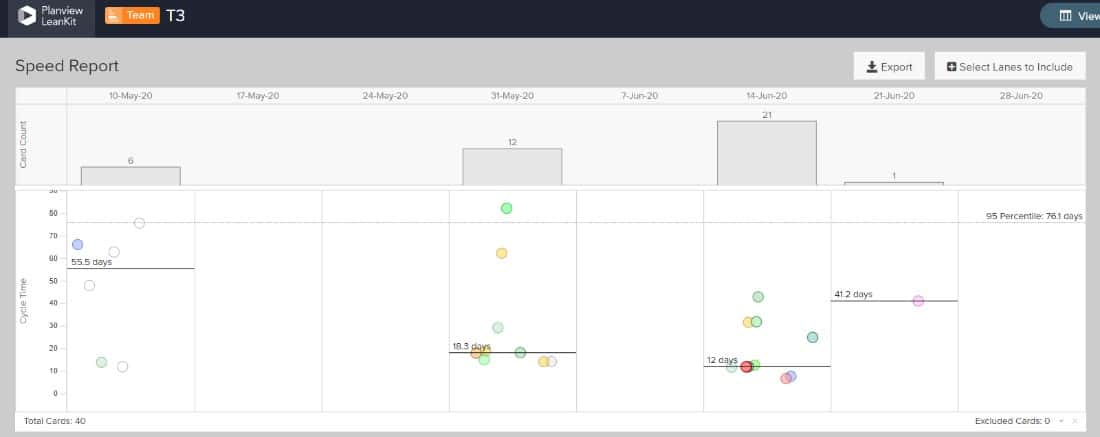

When organizations practice Lean manufacturing, they often track metrics like cycle time (shown above) to measure their delivery speed.

Cycle time is how long a card takes to travel from one point to another across the board. It can be used to measure the entire duration a card spends on the board, or the duration of any specific part of the total process. The clock starts when a card is pulled into the designated “Start” lane and ends when it reaches the designated “Finish” lane.

Many calculations are possible with cycle time and throughput metrics. Keep it simple in the beginning and only record the average cycle time of every card that was finished that week (i.e., the cards you counted to measure throughput).

Throughput is the number of items completed per time period. At the end of each week, record how many items were completed (i.e., moved to “Done” and never moved backwards). Track this number from week to week to see how changes made in your Kanban system affect how much total work actually gets done.

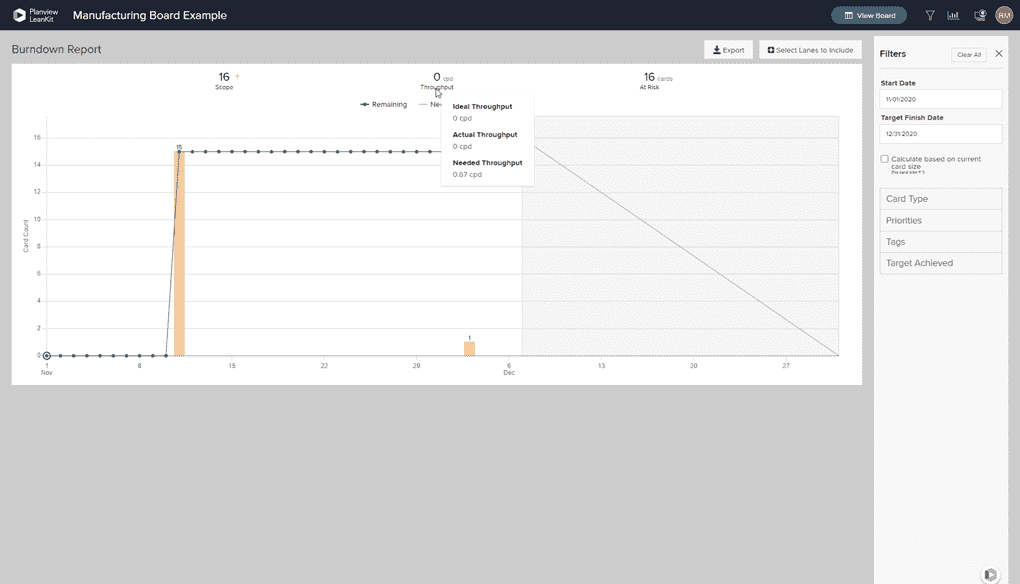

You can also view the board’s health along with Bottlenecked Lanes and Work in Process (by week) by clicking the heart icon.

TIP

Use Power BI to create your own reports and dashboards.

Prioritize Your Tasks

There’s more to using Kanban than assigning tasks on a board and monitoring metrics. You also need to implement a strategy that encourages your team to work more efficiently.

Here’s how you can do it:

- Prioritize your tasks by keeping the most important projects at the top of your work queue.

- Keep lines of communication open by encouraging on-platform communication with all participants working on tasks within a project.

- Modify and optimize team processes in real-time if the scope of the project changes.

- Choose a compatible Kanban platform that works well with your existing tools.

As you continue to seek improvements to your process, follow these ideas to keep the energy up among your team:

- Focus your experiments and metrics on improving one or more of your team’s capabilities, whether it’s quicker delivery, predictable delivery or the capability to deliver higher quality, measured in lower defect rates and instances of rework.

- Continue to encourage team ownership of the process and focus improvement efforts on the Kanban system, rather than individuals.

Set Work in Process or Work In Progress (WIP) Limits

To manage the flow of that work as it moves through our process, we use work-in-process (WIP) limits and the concept of a pull system to constrain how much work we tackle at one time. Limiting the number of work items that can be placed within certain lanes on your board prevents overloading your process or people with more work than can be performed. Combined with a pull system, in which people doing the work only begin tasks as they're ready to complete them, enables teams to complete work efficiently and quickly adapt to change rather than being overloaded with work.

Start tracking your current work in process by recording it on a weekly basis to analyze trends in the amount of work you have in process at any one time.

TIP

When you hit a WIP limit, stop doing the kind of work that adds to that queue. Instead, let the work continue to flow through the system. Go help a teammate or work on a task that doesn’t add WIP on the board.

Do Regular Board Maintenance

- Regularly “edit” your board.

- Make sure your board still reflects your process and isn’t getting filled up by stale cards.

- Keep a running list of “someday” ideas to review.

- Create a backlog or ideas lane on your board to reduce clutter and encourage ideation by storing ideas in an organized way and reviewing them regularly.

- Create an automated reminder for the team to add items to the backlog and set a recurring meeting to review them.

Have Regular Retrospectives

Retrospectives are held on a regular basis, whether weekly, bimonthly, or monthly. They give the team a focused opportunity to evaluate the health of the system, make adjustments, and devise experiments.

- At the end of every week, gather around the board to evaluate your Kanban system. Observe the flow of work and add a new question each week.

- When implemented effectively, standups and retrospectives are powerful tools for teams that seek transparency and open collaboration.

Effective standups and retrospectives empower team members and managers alike to observe flow, resolve issues, and run experiments, helping everyone stay more engaged and support a culture of continuous improvement.

More Resources

|

|

|||||||

|

|

|||||||

|

|

|||||||